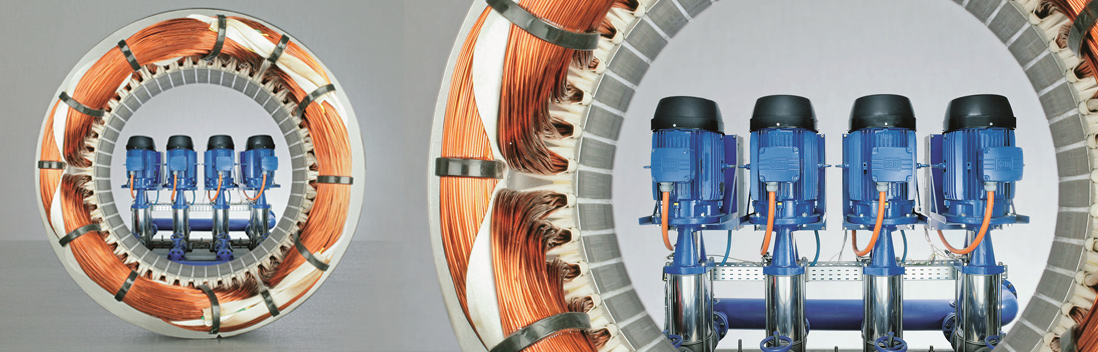

The motors is very important in the operation of machines employed in various industries. Since a company's performance and profitability depend on the efficiency and reliability of these machines, protection of the motors is the key. To keep these machines running like new, they depend on a proven electrical insulation system. The system provides protection from temperature changes, chemicals and moisture.

Product Summary

ELANTAS Zhuhai has various products to meet the requirements of large motor customers with long service history.

Epoxy resin has excellent resistance to chemicals. The unsaturated polyester resins has excellent penetration, good bondstrength. Water epoxy emulsions are environmental friendly resin with excellent bond strength and electrical properties.

Solutions For

- Reducing Emissions

- UL Recognition

- Medium Voltage Applications

- High Voltage Applications

- Severe Duty Applications

- Difficult Impregnat

| Product | Base Resin | Unique Characteristics | Viscosity @25°C,mPa·s | Cure Schedule | Application Method | Thermal Class |

| EPOXYLITE 006-0841 | EPOXY RESIN | Single component and solventless, low viscosity resin with excellent tank stability specifically designed for the harsh environments. | 650-800 | 6-12 hours @165°C | DIP | 180°C |

| Dobeckan® FT1052 | UNSATURATED POLYESTERIMIDE | Two components system , a tough hard cured material with very good mechanical and dielectric properties. It has very good long term thermal capacity and high bonding strength of windings impregnated . The cured material also displays very high resistance to tropical influences, solvents and their vapours, oil, and other chemicals. | 490-550 @ 23°C | 2-4 hours @130-150°C | DIP/TRICKLE/VPI | 180/200°C |

| EPOXYLITE 478 THIXO VPI RESIN | EPOXY RESIN | Single component, low viscosity, high thixotropic, low emission. | 1500-3000 | 3 hours @150°C | VPI | 180°C |

| EPOXYLITE 5070 | EPOXY RESIN | Single component, low viscosity, good penetration and high film build, the system is suitable for machines designed for use in hostile environments. | 4000-7000 | 4-6hours 165°C | DIP/VPI | 180/200°C |

| EPOXYLITE 213 PF | EPOXY RESIN | Two component, filled, chemically resistant, good wettability, heat/ambient curable epoxy resin system. Available in red version. | 225-375 | 24hours@25°C 1 hour@100°C | BRUSH/SPRAY | - |

| E300 | EPOXY RESIN | Single component, high thixotropic, filled, solventless, high bond strength. | 90000-120000 | 2 hours @150°C | BRUSH | 180°C |

| EM GRC59 | EPOXY EMULSION | No VOC water based epoxy emulsion with high bond strength and excellent electrical properties. This material exhibits superb chemical resistance in harsh environments. Available in various non-volatile content versions from 10-50%. | 600-2000 | 2-6 hours @150-165°C | DIP/ROLL DIP | 180°C |

| 073-1010 | SOLVENTED ALKYD VARNISH | Give a very good surface build in conjunction with excellent penetration and combines flexibility with good bond strength. It exhibits excellent chemical and water resistance. | 135-155s @ 21°C, B4 cup | 4-6 hours @130-160°C | DIP | 200°C |

| 009-0008 | ALKYD VARNISH | Single-component, fast air drying, anti-tracking, fungicidal varnish. Available in different color version | 100-125s @ 21°C, B4 cup | 45-60 minutes @20°C 15-20 minutes @80°C | DIP | 180°C |

| PED 50S PRE-CAT POLYESTER | UNSATURATED POLYESTER | The advantages of thisns. system are that it has low viscosity coupled with fast cure times for ultimate impregnation coupled with good cured resiliency to reduce noise in motor operation. | 90-130 | 2-6 hours @150-170°C | DIP/VPI | 200/220°C |

| Dobeckan® FT 1040 | UNSATURATED POLYESTERIMIDE | Two components system with excellent high temperature bond strength. The cured material displays very high resistance to tropical influences, solvents , oil, and other chemicals. | 110-130 cps @ 23°C | 2-4 hours @130-150°C | TRICKLE/ROLL DIP | 180°C |

| Ranvar R2003 | UNSATURATED POLYESTER | It exhibits good tank stability coupled with good bond strength, low shrinkage and chemical / moisture resistance. | 350-650 | 2-4 hours @150°C | DIP/VPI | 180°C |

| Dobeckan® MF 8044 | UNSATURATED POLYESTERIMIDE | Single component, low emissions, good penetration, excellent heat resistance ,strong centrifugal force. Available in UV curing version. | 6500-7500 | 40 minutes @150°C | TRICKLR/DIP | 180°C |

| Dobeckan® FT 2015 | UNSATURATED POLYESTERIMIDE | Single component, low odor, high bonding strength ,the cured material displays very high resistance to tropical influences, solvents , oil, and other chemicals. Available in high thixotrophy version. | 85-95s @ DIN 4#,23°C | 2-6 hours @120-150°C | DIP/VPI | 200°C |

| Elan-protect® UP 142 | UNSATURATED POLYESTERIMIDE | Single component, high thixotropic, good penetration ,low emissions, excellent heat resistance ,strong centrifugal force. Available in high thixotrophy and UV curing versions. | 900-1500 | 2hours@150°C 1hours@160°C | ROLL DIP/DIP | 180°C |